For lamination the internal layers of the pcb are subjected to under extreme temperature 375o f and pressure 275 to 400 psi.

Pcb laminator temperature.

Copper coated laminate fr4 treated by internal layer imaging is the.

I describe here the way i create images onto diy printed circuit boards using the common toner transfer method but less commonly with a paper laminator.

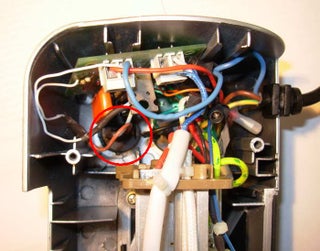

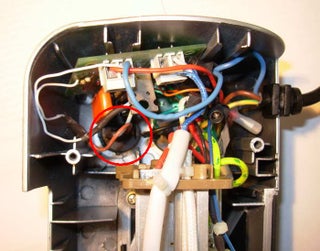

So i decided to hack the laminator by slowing down its rolls motor using a triac controller.

That s about the right amount of heat for the toner to fuse and stick to the copper.

Always refer to your roll laminator s user manual for information on temperature settings.

For pcbs the tg corresponds to the temperature at which fiberglass becomes amorphous during lamination at high temperatures and under pressure of the different material layers.

For better results make sure to repeat the process of pcb lamination at least 10 times to ensure that the toner is properly transferred to the copper.

In general however these are the temperature settings you would use.

Why picking the right laminate is so important.

What are the most important laminate properties.

How are laminates classified.

Instead of laminating the pcb in 10 even 20 passes the motor is switched on 1 2 second then off 10 seconds off times of 3s 6 s can also be selected.

This procedure is implemented when laminating with a photosensitive dry resist.

Iii laminate what is a laminate.

What testing does ipc 4101 require us to do.

Picking the right high temperature pcb laminate materials can be crucial to your operation.

How do i read an ipc 4101 slash sheet.

What is a qpl.

How does our part number relate to the ipc 4101 line callout.

Why a laminator is superior over the use of a house hold iron.

It is not the pcb maximum operating temperature but rather that which the pcba can endure for a short time before it deteriorates.

High temperatures can quickly lead to malfunctions and permanent damage.

Temperature is an important element of safety reliability and performance in printed circuit boards pcbs.

Making use of a high temperature laminate in these situations is highly recommended.

Be aware that if you decide to buy one it might be difficult to replace the components that adjust the temperature.

Increasing plate thickness and width.

To get a toner printed image to transfer to a metal surface pcb copper laminate or other metals for chemical milling we have 3 variables to control.

For general purpose film.

3 mil runs at 275º 300º.